Epoxy resin flooring has emerged as a popular choice for both residential and commercial spaces in India, thanks to its durability, aesthetic appeal, and ease of maintenance. However, one of the most significant factors that potential buyers consider before investing in epoxy flooring is the cost. In this comprehensive guide, we will delve into the various factors that influence the epoxy resin flooring cost in India, the different types of epoxy resin flooring available, and tips to get the best value for your investment.

What is Epoxy Resin Flooring?

Epoxy resin flooring is a type of flooring made from a combination of resin and hardeners. When these two components are mixed, they chemically react to form a rigid plastic material that is strong, resistant to degradation, and adheres well to its substrate. The result is a durable and visually appealing flooring option that can be customized in terms of color, texture, and finish.

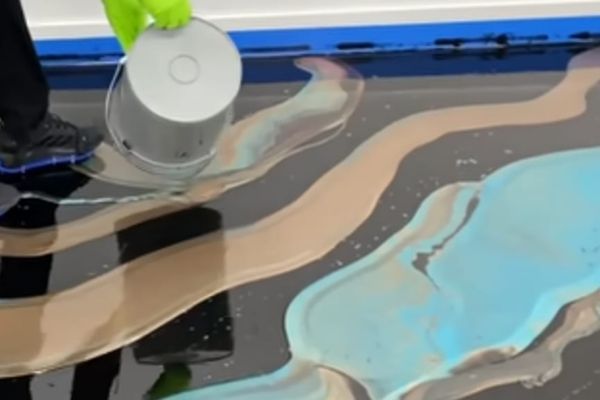

Epoxy resin flooring is a type of flooring system that consists of multiple layers of epoxy, a thermosetting polymer, applied to a concrete substrate. The result is a durable, seamless, and highly resilient surface that can withstand heavy traffic, chemical spills, and other wear and tear.

Epoxy flooring is known for its glossy finish, which can be customised with various colours, patterns, and even 3D designs. It is widely used in industrial settings, commercial spaces, garages, and even in residential areas like bedroom, bathroom, kitchens and basements.

Types of epoxy resin flooring

- Self-Leveling Epoxy Floors

- Epoxy Mortar Floors

- Quartz-Filled Epoxy Floors

- Anti-Static Epoxy Floors

- Epoxy Flake Floors

Average costs of epoxy resin flooring in india

- Basic Epoxy Flooring: Estimated cost per square foot.

- Mid-Range Epoxy Flooring: What to expect for more durable options.

- High-End Epoxy Flooring: Costs for premium features and finishes.

Factors affecting epoxy resin flooring cost in India

- Type of Epoxy Used: Describe how different types of epoxy affect costs.

- Floor Preparation: Discuss the cost implications of surface preparation.

- Labor Costs: Analyze how labor rates in different regions affect pricing.

- Area Coverage: Explain how the size of the area affects the overall cost.

- Thickness of the Coating: The impact of coating thickness on pricing.

- Design Complexity: Costs associated with custom designs or patterns.

- Additional Features: Anti-slip properties, UV resistance, etc., and their cost implications.

- Market Rates: Current market trends in India.

Comparison of epoxy flooring with other flooring options

- Epoxy Resin vs. Tiles

- Epoxy Resin vs. Concrete Polishing

- Epoxy Resin vs. Wooden Flooring

Pros and cons of epoxy resin flooring

- Advantages: Durability, aesthetics, low maintenance, etc.

- Disadvantages: Initial cost, installation time, etc.

Installation process and cost breakdown of epoxy flooring

- Surface Preparation: Steps and associated costs.

- Priming: Why it’s important and its cost.

- Applying the Epoxy: The process and its cost.

- Curing and Finishing: Time required and cost implications.

Maintenance costs of epoxy resin flooring

- Routine Cleaning: Costs associated with regular maintenance.

- Repairs and Refurbishing: Cost implications for damages or wear.

- Longevity and Lifespan: How maintenance impacts the overall cost over time.

Where to Buy Epoxy Resin in India

- Top Suppliers and Manufacturers: A list of reputed suppliers.

- Online Marketplaces: Best platforms for purchasing epoxy resin in India.

- Local Contractors and Installers: Hiring tips and cost considerations.

Tips to Reduce Epoxy Resin Flooring

- Bulk Purchases: Discounts and savings on large projects.

- DIY Installation: When it might be feasible and cost-effective.

- Off-Peak Installation: Cost benefits of scheduling during non-peak times.

Conclusion

- Summary of Cost Factors

- Final Thoughts on Investing in Epoxy Resin Flooring

Estimating the total epoxy resin flooring cost in India.

To give you a better idea of total epoxy resin flooring cost in India, let’s break down the costs for a hypothetical project covering an area of 1,000 square feet with self-levelling epoxy resin flooring cost in India.

- Epoxy Material: INR 70 per square foot

- Surface Preparation: INR 25 per square foot

- Labour: INR 25 per square foot

- Additional Costs (Primer, Sealant, etc.): INR 25 per square foot

Total Cost = 70 + 25 + 25 + 25 = INR 145 per square foot

For a 1,000 square feet area, the total cost would be approximately:

INR 145 x 1,000 = INR 1,45,000

This is a rough estimate of epoxy resin flooring cost in India can vary depending on the factors mentioned below.

Types of epoxy resin flooring

When considering epoxy flooring, it’s essential to understand the different types available, as each type has its specific application, benefits, and cost implications.

1. Self-Leveling epoxy floors cost INR 45 to 80 per square foot

Self-leveling epoxy floors are applied to new, old, cracked or damaged concrete floors. It gives the surface a level, study, and smooth texture. These types of floors come in a variety of colours. They are typically used in industrial environments, warehouses, and commercial spaces due to their ability to withstand heavy traffic. The cost of self-leveling epoxy resin flooring cost in india is influenced by the area size and thickness of the coating required.

2. Epoxy mortar flooring cost INR 150 to 300 per square foot

Epoxy mortar floors are among the strongest epoxy floors available. They are made by combining epoxy with graded sand or quartz, creating a highly durable and impact-resistant surface. These floors are ideal for areas exposed to heavy machinery or high-impact activities, making them common in manufacturing plants and garages. The cost is generally higher due to the additional materials and labor involved.

3. Quartz-Filled epoxy flooring cost INR 200 to 350 per square

Quartz-filled epoxy floors incorporate colored quartz grains within the epoxy resin, creating a decorative and slip-resistant surface. These floors are often used in commercial kitchens, locker rooms, and showrooms. The inclusion of quartz increases the cost compared to basic epoxy flooring but offers added aesthetic value and slip resistance.

4. Anti-Static epoxy flooring cost INR 120 to 250 per square

Anti-static epoxy floors are designed to prevent static electricity buildup, making them essential in environments where sensitive electronic equipment is used. The installation process for anti-static epoxy is more complex, and the materials are specialized, which increases the overall cost.

5. Epoxy flake flooring cost INR 300 to 450 per square foot

Epoxy flake floors are decorative floors where colored chips or flakes are added to the epoxy resin. This type of flooring is popular in residential garages, showrooms, and retail spaces. The cost of epoxy flake floors varies based on the complexity of the design and the size of the area.

Average costs of epoxy resin flooring in india

To provide a clearer understanding of what to expect, here is a breakdown of the average cost of epoxy resin flooring in India, categorized by the type and quality of flooring.

1. Basic epoxy flooring cost INR 45. to 120 per square feet

Basic epoxy flooring, suitable for residential use or light commercial applications, typically costs between INR 45 to INR 120 per square foot. This cost covers standard epoxy resin and a basic installation process without any additional features.

2. Mid-Range epoxy flooring cost INR 150 to 300 per square

For more durable options that can withstand moderate to heavy traffic, the cost ranges from INR 150 to INR 300 per square foot. This price range includes self-leveling epoxy floors and quartz-filled epoxy, which offer better durability and aesthetics.

3. High-End epoxy flooring cost INR 300 to 800 per square

High-end epoxy flooring, which includes anti-static floors, epoxy mortar floors, and custom designs, can cost anywhere from INR 300 to INR 800 per square foot. These options are typically used in specialized industrial environments or for premium commercial spaces.

Factors affecting epoxy resin flooring cost in india

Several factors influences epoxy resin flooring cost in India, making it essential to understand these elements to estimate your budget accurately.

1. Type of Epoxy Used

The type of epoxy used is one of the primary determinants of cost. Higher-quality epoxies, such as those used for industrial applications or anti-static floors, tend to be more expensive than basic epoxy resins.

2. Floor Preparation

Proper floor preparation is crucial for the success of epoxy flooring. This process may include cleaning, repairing cracks, and leveling the surface. The extent of preparation required will directly impact the cost, with more extensive repairs or leveling increasing the overall expense.

3. Labor Costs

Labor costs can vary significantly depending on the region in India and the complexity of the installation. In urban areas, labor rates are generally higher than in rural regions. Additionally, more intricate designs or thicker coatings will require more labor, increasing costs.

4. Area Coverage

The size of the area to be covered plays a significant role in determining the overall cost. Larger areas may benefit from bulk pricing on materials, but they also require more labor, which can offset these savings.

5. Thickness of the Coating

The thickness of the epoxy coating is another factor to consider. Thicker coatings provide more durability and longer lifespan but also increase material costs. A typical epoxy floor might range from 1mm to 5mm in thickness, with thicker coatings being more suitable for industrial applications.

6. Design Complexity

Custom designs, such as logos, patterns, or multi-colored finishes, add to the cost of epoxy flooring. The complexity of the design will determine the amount of additional labor and materials required.

7. Additional Features

Special features, such as anti-slip properties, UV resistance, or chemical resistance, can add to the overall cost. These features are often necessary for specific environments, such as outdoor areas or chemical plants.

8. Market Rates

Current market rates for materials and labor also play a role in determining costs. These rates can fluctuate based on factors such as demand, availability of materials, and economic conditions.

Comparison of epoxy resin flooring with other flooring options

When considering epoxy resin flooring cost in india, it’s helpful to compare it with other popular flooring options to understand its value proposition.

1. Epoxy Resin vs. Tiles

Epoxy resin flooring is often compared to tiles, particularly ceramic or vitrified tiles. While tiles are generally less expensive, epoxy flooring offers superior durability, chemical resistance, and a seamless finish. Epoxy is also less prone to cracking and easier to clean, making it a better option for industrial and commercial spaces.

2. Epoxy Resin vs. Concrete Polishing

Polished concrete is another popular flooring option, particularly in industrial settings. While polished concrete is generally cheaper, epoxy resin offers better chemical resistance, customization options, and a smoother finish. Epoxy is also easier to repair and maintain, making it a more practical choice for areas exposed to heavy traffic or chemicals.

3. Epoxy Resin vs. Wooden Flooring

Wooden flooring is often chosen for its aesthetic appeal and warmth. However, it is more susceptible to damage from moisture, chemicals, and heavy impacts. Epoxy resin flooring, while more expensive initially, offers better durability, lower maintenance costs, and greater versatility in design.

Pros and cons of epoxy resin flooring

To help you make an informed decision, let’s explore the advantages and disadvantages of epoxy resin flooring.

Advantages

- Durability: Epoxy resin floors are highly durable and resistant to wear, making them ideal for high-traffic areas.

- Aesthetic Appeal: Epoxy floors can be customized in various colors, patterns, and finishes, enhancing the visual appeal of any space.

- Low Maintenance: Epoxy floors are easy to clean and require minimal maintenance, reducing long-term costs.

- Chemical Resistance: Epoxy is resistant to a wide range of chemicals, making it suitable for industrial environments.

- Seamless Surface: The seamless finish of epoxy floors eliminates the crevices where dirt and bacteria can accumulate, promoting a cleaner environment.

Disadvantages

- Initial Cost: The upfront cost of epoxy flooring can be higher than other options, particularly for high-end or custom designs.

- Installation Time: Epoxy flooring requires a multi-step installation process, including curing time, which can take several days.

- Slippery When Wet: While epoxy is generally non-slip, it can become slippery when wet, especially if a smooth finish is used. Anti-slip additives can be included to mitigate this issue.

- Surface Preparation: Proper surface preparation is critical to the success of epoxy flooring, and any mistakes in this phase can lead to costly repairs.

Installation process and cost breakdown of epoxy resin flooring

Understanding the installation process of epoxy resin flooring can help you better grasp where the costs are coming from.

1. Surface Preparation

The first step in installing epoxy flooring is preparing the surface. The surface where the epoxy will be applied must be clean, dry and free of any contaminants. This often involves grinding or shot blasting to create a rough surface for the epoxy to adhere to. This process may include cleaning, repairing cracks, and leveling the surface. Depending on the condition of the existing floor, this step can be labor-intensive and costly, often accounting for 10-30% of the total project cost.

2. Priming

After surface preparation, a primer is applied to ensure proper adhesion of the epoxy to the substrate. Priming typically costs an additional INR 20-50 per square foot but is a crucial step in ensuring the longevity of the flooring.

3. Applying the Epoxy

The epoxy is applied in multiple layers, with each layer requiring time to cure. The number of layers and the type of epoxy used will affect the cost. Typically, applying the epoxy accounts for the largest portion of the project cost, ranging from INR 50 to INR 300 per square foot.

4. Curing and Finishing

After the final layer is applied, the epoxy must cure for several hours to days, depending on the product used. Once cured, the floor is inspected, and any necessary finishing touches are applied. This phase can add INR 10-30 per square foot to the total cost.

Maintenance costs of epoxy resin flooring

While epoxy resin flooring is known for its low maintenance, there are still some costs associated with keeping it in good condition.

1. Routine Cleaning

Routine cleaning of epoxy floors is relatively inexpensive, usually requiring just a mop and a mild detergent. Regular cleaning helps maintain the floor’s appearance and prevents dirt buildup, which can cause scratches.

2. Repairs and Refurbishing

Over time, epoxy floors may develop small cracks or chips, particularly in high-traffic areas. Repairing these minor damages is essential to prevent them from worsening. The cost of repairs depends on the extent of the damage but generally ranges from INR 10 to INR 50 per square foot.

3. Longevity and Lifespan

With proper care, epoxy floors can last 10-20 years or more. Investing in high-quality epoxy and proper installation can extend the lifespan, reducing the need for frequent repairs or replacement.

Where to buy epoxy resin flooring in india

Finding a reliable supplier or contractor is crucial for getting the best results and value for your money.

1. Top Suppliers and Manufacturers

India has several reputable suppliers and manufacturers of epoxy resin, including Asian Paints, Pidilite Industries, and Berger Paints. These companies offer a wide range of epoxy products suitable for different applications.

2. Online Marketplaces

Online marketplaces such as Amazon India, Flipkart, and IndiaMART offer a variety of epoxy resin products. These platforms allow you to compare prices, read reviews, and make informed purchasing decisions.

3. Local Contractors and Installers

Hiring a local contractor with experience in epoxy flooring is essential for a successful installation. Look for contractors who have a proven track record, can provide references, and offer warranties on their work.

Tips to reduce epoxy resin flooring costs

If you’re looking to save on epoxy resin flooring costs, consider the following tips:

1. Bulk Purchases

If you’re covering a large area, buying materials in bulk can lead to significant savings. Many suppliers offer discounts for large orders, which can reduce the overall cost.

2. DIY installation

For smaller projects, consider a DIY installation if you have the necessary skills and tools. While this approach can save on labor costs, it’s essential to follow all installation guidelines carefully to avoid costly mistakes.

3. Off-Peak installation

Scheduling your installation during off-peak times, such as during the monsoon season when demand is lower, can result in lower labor costs. Many contractors offer discounts during these periods to keep their schedules full.

Conclusion

Epoxy resin flooring is a durable, versatile, and aesthetically pleasing option for both residential and commercial spaces in India. While the initial cost may be higher than other flooring options, its longevity, low maintenance, and customization possibilities make it a worthwhile investment. By understanding the factors that influence the cost and exploring ways to reduce expenses, you can make an informed decision that fits your budget and meets your needs.

In summary, epoxy resin flooring costs in India can range from INR 50 to INR 800 per square foot, depending on the type, quality, and complexity of the installation. Whether you’re looking for a basic solution for your home or a high-end option for an industrial setting, there’s an epoxy flooring option to suit your needs.