Resin Code 3: Polyvinyl Chloride (PVC)

Polyvinyl Chloride, commonly known as PVC and identified by Resin Code 3, is one of the most versatile and widely used plastics. Known for its durability and resistance to environmental degradation, PVC is found in a variety of applications ranging from construction materials to medical devices. In this article, we will explore the characteristics, uses, benefits, recycling processes, and environmental impact of PVC.

What is PVC?

Polyvinyl Chloride (PVC) is a synthetic plastic polymer produced by polymerizing vinyl chloride monomers. It comes in two main forms: rigid (sometimes abbreviated as RPVC) and flexible. The addition of plasticizers makes PVC flexible and suitable for a wide range of applications.

Common Uses of PVC

PVC’s versatility makes it useful in many industries. Some of its common uses include:

- Construction Materials: PVC is widely used for pipes, window frames, siding, and flooring due to its strength and durability.

- Medical Devices: Flexible PVC is used in medical tubing, blood bags, and IV containers because it can be sterilized and is biocompatible.

- Packaging: PVC is used in packaging, including shrink wraps, blister packs, and cling films.

- Consumer Goods: Items such as credit cards, toys, and imitation leather products are often made from PVC.

- Electrical Insulation: PVC is used as insulation for electrical cables due to its excellent fire-retardant properties.

Benefits of PVC

- Durability: PVC is highly resistant to wear and tear, chemicals, and weathering, making it ideal for long-term applications.

- Cost-Effective: PVC is relatively inexpensive to produce and process, contributing to its widespread use.

- Versatility: The ability to make PVC rigid or flexible allows it to be used in a variety of products and industries.

- Fire Resistance: PVC has inherent fire-retardant properties, adding a layer of safety to its applications.

Recycling PVC

Recycling PVC poses certain challenges due to the presence of additives and potential release of harmful chemicals. However, the recycling process typically involves:

- Collection: PVC waste is collected from post-consumer and post-industrial sources.

- Sorting: The collected PVC is sorted to remove contaminants and separate it from other types of plastics.

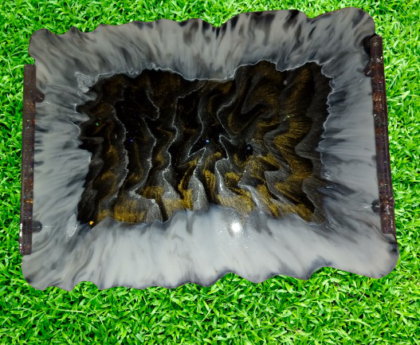

- Shredding: The sorted PVC is shredded into small flakes.

- Cleaning: The flakes are washed to remove any impurities.

- Reprocessing: The clean PVC flakes are melted and reformed into new products. This can include pipes, flooring, and industrial applications.

Environmental Impact

While PVC is useful and versatile, it does have some environmental concerns:

- Toxicity: The production and disposal of PVC can release harmful chemicals, including dioxins, which are hazardous to health and the environment.

- Recycling Challenges: PVC’s chlorine content and the presence of various additives complicate the recycling process.

- Non-Biodegradable: PVC does not biodegrade, contributing to long-term environmental pollution if not properly managed.

Advantages of Recycling PVC

Despite the challenges, recycling PVC offers several environmental benefits:

- Waste Reduction: Recycling PVC helps reduce the amount of plastic waste in landfills.

- Resource Conservation: Using recycled PVC conserves raw materials and reduces the need for virgin plastic production.

- Energy Savings: Recycling PVC can save energy compared to producing new PVC from raw materials.

Conclusion

Resin Code 3, or PVC, is a highly versatile plastic that plays a crucial role in various industries due to its durability, cost-effectiveness, and fire-resistant properties. However, its environmental impact and recycling challenges require careful management. By understanding the importance of PVC and supporting recycling efforts, consumers and industries can help mitigate its environmental footprint. Always check for the resin code on plastic products and adhere to local recycling guidelines to ensure that PVC is properly managed and recycled.

4o